How To Repair A Conveyor Belt

Introduction to Conveyor Belt Damage and Repair

In our postal service "Mining & Quarrying: Belzona'due south Top 5 Application Areas" nosotros listed the repair of damaged safety components and equipment as one of the top application areas in the Mining manufacture. This type of problem is regularly associated with conveyor belts in particular and conveying systems as a whole. Primarily, conveyor belts are exposed to excessive wear as a result of the materials they transport and the friction generated from the rough sliding and impact of these hard materials. As part of their design, the equipment surfaces are expected to absorb some of the energy this impact, yet jagged and sharp material can stillpenetrate the prophylactic material, vehement and splitting the conveyor belt.

The utilize of conveyor belts and systems is quite all-encompassing across many industries: mining, pulp/paper, food processing, pharmaceutical, agricultural, automotive, packaging, and much more. Failure of the belts and/or components of the carrying systems may cause production halts and jeopardize product quality.

How conveyor belts are repaired using traditional methods

The most traditional rubber repair technique inside the industry is vulcanization. This comprises heat and pressure being applied to rubber components, creating a strong chemical bail. Whilst this does offering a long-lasting repair, the procedure besides frequently relies on very specific ecology conditions and equipment. Birthday, vulcanization requires time for a specialized coiffure and equipment to be brought on to the site, necessitating long shutdowns.

These shutdowns can be costly and inefficient, peculiarly when heavy industrial belts are capable of moving over 5,500miii (194,231ftthree) per hour when fully loaded. That's enough to fill an Olympic pond pool in merely less than 30 minutes!

Using Belzona 2311 to prepare a conveyor chugalug

Cold cure resin conveyor belt patching materials offer an culling and distinctly dissimilar solution. They can be applied in situ without specialist tools, thus eliminating the need for hot repair processes. This ensures a fast return to service. Moreover, they offer a versatile repair where durability and elasticity, also as good chafe and tear resistance, are required.

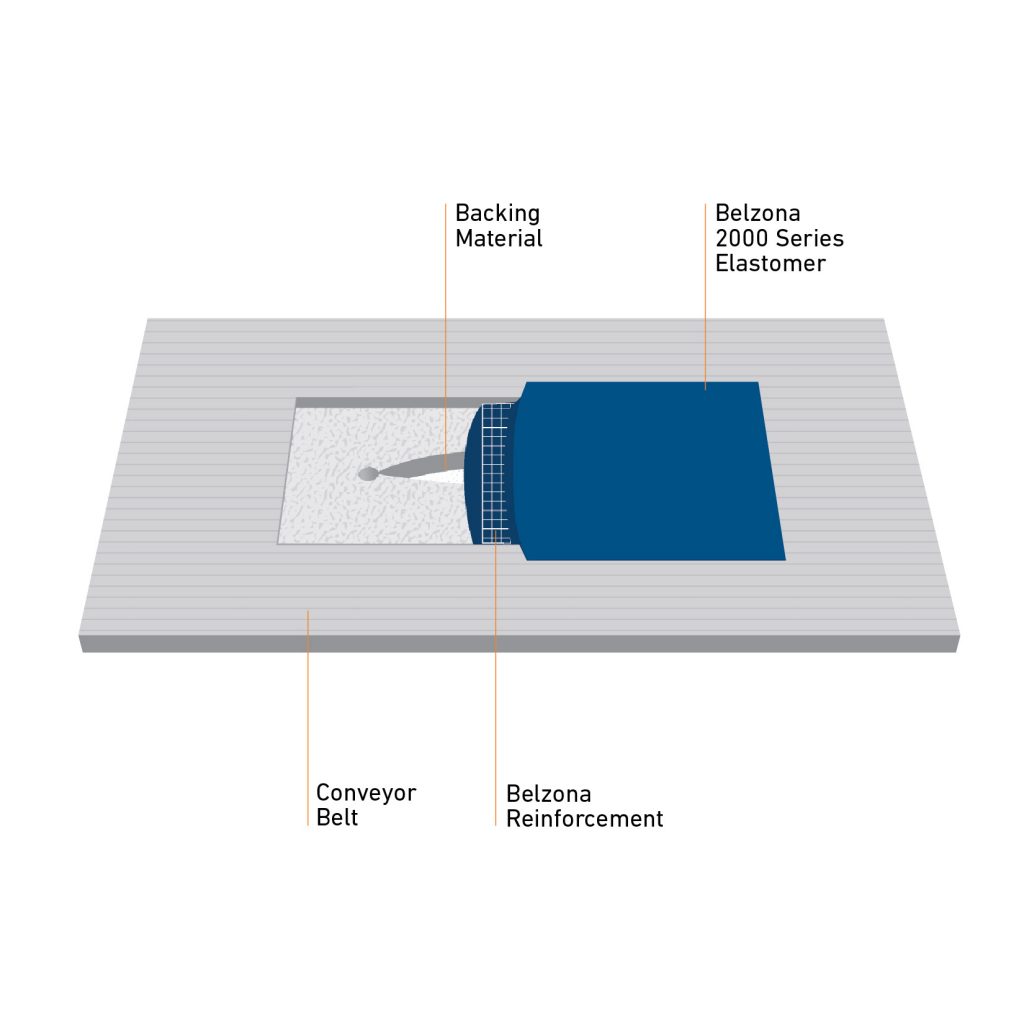

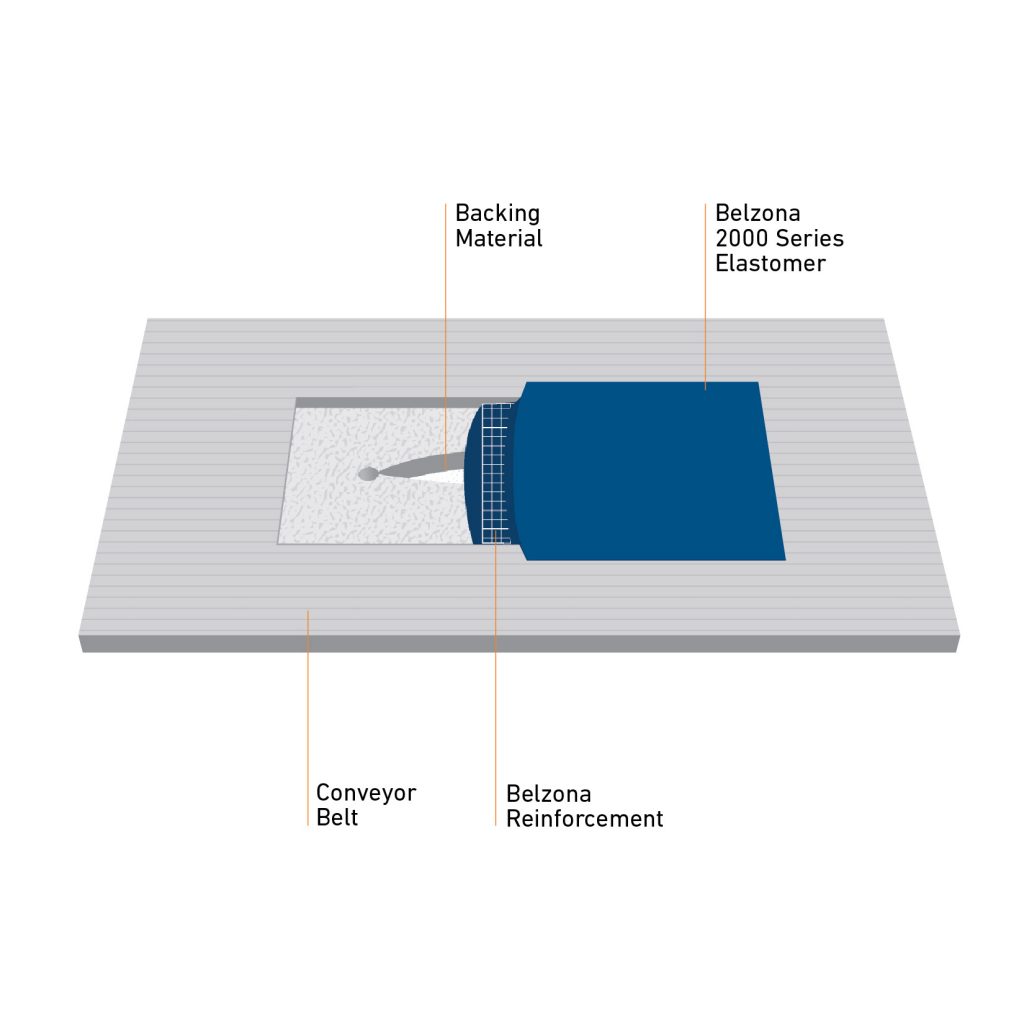

Cartoon: Ripped Conveyor Chugalug Repair with Belzona 2311

Video: How to repair a Conveyor Belt With Belzona 2311

- Post author:Yulia Burova

- Postal service published:June 28, 2022

- Post category:Belzona Educates / How To Series

- Post comments:1 Comment

- Opens in a new window

Opens in a new window Opens in a new window Opens in a new window Opens in a new window Opens in a new window Opens in a new window Opens in a new window

INTRODUCTION TO CONVEYOR Chugalug DAMAGE AND REPAIR

In our post "Mining & Quarrying: Belzona'due south Tiptop 5 Application Areas" we listed the repair of damaged safe components and equipment as one of the top awarding areas in the Mining industry. This blazon of problem is regularly associated with conveyor belts in particular and conveying systems every bit a whole. Primarily, conveyor belts are exposed to excessive habiliment as a result of the materials they send and the friction generated from the rough sliding and impact of these hard materials. As function of their design, the equipment surfaces are expected to absorb some of the energy this bear upon, yet jagged and sharp material can stillpenetrate the rubber material, violent and splitting the conveyor chugalug.

The utilize of conveyor belts and systems is quite extensive across many industries: mining, pulp/paper, food processing, pharmaceutical, agricultural, automotive, packaging, and much more. Failure of the belts and/or components of the conveying systems may cause product halts and jeopardize product quality.

Traditional repair solutions

The virtually traditional prophylactic repair technique within the manufacture is vulcanization. This comprises heat and pressure being applied to rubber components, creating a strong chemic bond. Whilst this does offer a long-lasting repair, the process too frequently relies on very specific environmental conditions and equipment. Altogether, vulcanization requires time for a specialized crew and equipment to be brought on to the site, necessitating long shutdowns.

These shutdowns can be plush and inefficient, especially when heavy industrial belts are capable of moving over five,500m3 (194,231ft3) per hour when fully loaded. That's enough to fill an Olympic pond puddle in only less than 30 minutes!

Belzona solution

Cold cure resins offer an alternative and distinctly different solution. They tin can be practical in situ without specialist tools, thus eliminating the need for hot repair processes. This ensures a fast render to service. Moreover, they offer a versatile repair where durability and elasticity, every bit well equally skilful abrasion and tear resistance, are required.

Belzona Elastomer Systems – Put It to the Exam

Click here to sentinel a video demonstration.

BELZONA HOW-TO

Cartoon: Ripped Conveyor Belt Repair with Belzona 2311

VIDEO: HOW TO REPAIR A CONVEYOR Chugalug WITH BELZONA 2311

For this repair, we used Belzona 2311, Belzona 2911, Belzona 9341 (Reinforcement Tape) and some tools from our machine shop. The repair did not crave disassembly of the belt. Start, the tear was terminated by drilling holes at each end of the tear. The safe was then undercut and the acme layer was removed. The substrate was abraded until a woolly finish was achieved. The surface area nether the tear was taped to forbid the product from leaking through. Belzona 2311 was thoroughly mixed and practical over the tear firmly to ensure an optimal bond with the substrate. Additional material was applied to a pre-cut slice of the reinforcement tape, which then was embedded over the repair area and encapsulated with the remaining mixed textile. In one case the product cured, the chugalug was out dorsum to service.

Step-By-Step Instructions Of Conveyor Chugalug Repair With Belxona 2311

-

Finish the tear by drilling -

Undercut safe and remove information technology -

Remove the acme layer -

Abrade the surface to a wooly finish -

Castor away loose parts -

Cover the surface nether the tear -

Tape off the repair area -

Apply conditioner to the repair area -

Mix Belzona 2311 -

Utilise Belzona 2311 -

Wet out and embed the tape into the practical textile -

Encapsulate the tape with the remaining material -

Remove tape, the awarding is complete

Belzona's epoxy solutions tin be used to repair conveyor belts. Belzona besides offers solutions to an extensive range of engineering bug and repair situations.

Interested in purchasing Belzona'due south epoxy-based composites?

How To Repair A Conveyor Belt,

Source: https://blog.belzona.com/ripped-conveyor-belt-repair/

Posted by: johnstonhoot1998.blogspot.com

0 Response to "How To Repair A Conveyor Belt"

Post a Comment